Screenprinting - 2 of 3

Once the design is complete the screen is placed over the stencil and the film adhered to the mesh with an activating solution. When dry the backing is peeled off and the edges of the screen taped to seal them.

As with the stencil film each colour to be printed requires a separate black and white image but now it needs to be clean white and dense black.

PHOTO EMULSION STENCILS

The screen is prepared by covering with a film of light sensitive emulsion. The screen must then be stored in the dark until it is ready to be exposed.

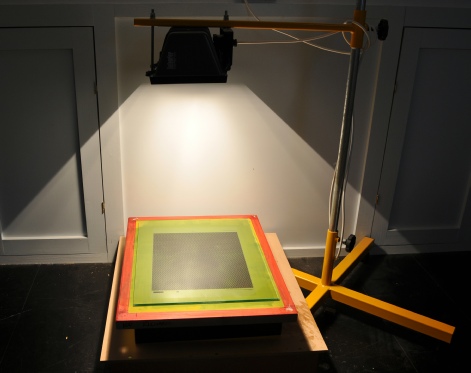

The design is transferred onto a transparency film via an inkjet printer. The transparency is then placed face down on the bottom of the prepared screen, held in place with a sheet of glass, and exposed to a light source.

Using a 1000watt halogen lamp the screen is exposed for between 2 to 4 minutes depending on the size of the screen and consequent distance from the lamp.